A reliable hitch transforms a tractor from a single-purpose machine into a versatile workhorse. Whether you need to pull a small trailer, reposition implements, or attach tow-behind equipment, understanding 3-point hitch 2” receiver quick hitches, tractor mover drawbars, 3-pt quick hitches for farm implements, and subcompact trailer hitches for Category 1 tractors is essential. This article explains what each product is, how they work, compatibility considerations, installation and safety tips, maintenance best practices, buying criteria, common use cases, and a troubleshooting checklist. Read on to learn how to choose and use the right hitch solution for your tractor and tasks.

What these hitches are (simple definitions)

3-Point Hitch 2” Receiver Quick Hitch Compatible

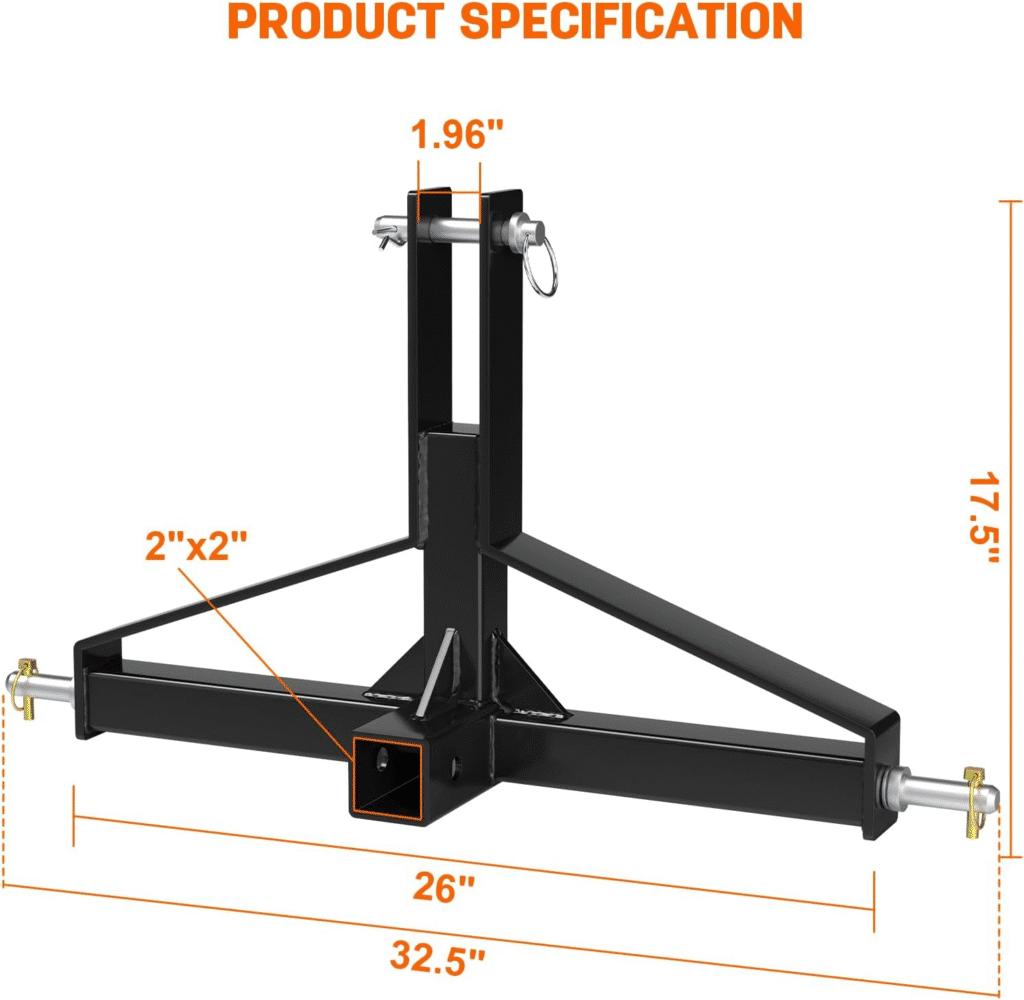

This refers to an adapter system that mounts on a tractor’s 3-point hitch and provides a standard 2-inch square receiver (the same size as many ATV/utility trailer receivers). The “quick hitch compatible” designation means the adapter can be rapidly attached or detached using the tractor’s quick hitch mechanism (top link and lower link quick-connect pins), so you can swap trailers and implements quickly without tools.

Tractor Mover Drawbar Hitch

A drawbar hitch (sometimes called a tractor mover or tow bar) attaches between the tractor’s 3-point hitch or drawbar mount and a trailer or implement using a pin or clevis. It’s a simple, robust connection used for towing trailers, wagons, and certain implements. Drawbars can be fixed-length or telescoping, and many are adjustable to align with the trailer coupler height.

3-Pt Quick Hitch Farm Equipment

A “3-point quick hitch” is an accessory that allows implements designed for the tractor’s lower lift arms and top link to be attached or detached quickly. There are several quick-hitch systems (manufacturer-specific and universal) that speed up implement changes — ideal for farmers and landscapers who switch tools frequently.

Subcompact Trailer Hitch for Tractor — Category 1

Category 1 is the smallest standardized 3-point hitch class, used on subcompact and many compact tractors. A subcompact trailer hitch designed for Category 1 tractors provides towing capability appropriate for lighter trailers and garden implements. These hitches maintain safe hitch height, implement geometry, and load ratings for smaller tractors.

Why choose these solutions? (Primary benefits)

- Speed & Convenience: Quick hitches and 2” receiver adapters dramatically reduce time spent swapping equipment. That’s a huge productivity boost when tasks require multiple attachments.

- Versatility: A 2” receiver opens compatibility with a broad range of off-the-shelf trailers, hitches, and accessories (ball mounts, pintle hooks, cargo carriers).

- Improved Maneuverability: Drawbar hitches create a rigid towing pivot that’s often preferable for trailer handling compared to rope or chain connections to the 3-point.

- Compact Tractor Optimization: Category 1 hitches are sized and rated specifically for subcompact tractors, ensuring you don’t overload the tractor or change its center of gravity unexpectedly.

- Safety & Control: Purpose-built hitches ensure correct load distribution, minimize implement sag, and provide secure pin-and-clevis or ball connections that are safer than improvised tie-downs.

Compatibility & sizing — what to check before you buy

1. Hitch Category and Pin Dimensions

- Category 1 three-point hitches use ⅞″ (22 mm) lift-arm pins and a ⅝″ (16 mm) top-link pin in many historical specs — but always confirm manufacturer specs. Ensure any quick hitch, drawbar, or receiver adapter is explicitly rated for Category 1 or match your tractor’s category.

2. Weight Ratings (GTW / Tongue Load)

- Check the hitch’s Gross Trailer Weight (GTW) and maximum tongue weight. Subcompact tractors usually have much lower towing capacities than full-size tractors; pick components rated well within your tractor’s limits.

3. Receiver Size

- A “2-inch receiver” is standardized: the shank that slides into the receiver tube should be 2” square. Confirm that ball mounts and accessories you plan to use are 2” shank compatible.

4. Quick Hitch System Type

- Quick hitch designs vary: some are universal-style while others are brand-specific (e.g., older Farmall/New Holland variants). If you already own a quick hitch, choose compatible adapters; if not, consider a universal top-and-lower-pin quick hitch that fits Category 1.

5. Top Link Length & Clearance

- When adding a receiver adapter to the 3-point, make sure the top link and lower link geometry won’t interfere with ground clearance or the tractor’s lift mechanism.

6. Braking & Lighting Requirements

- If you’ll tow trailers on public roads, local laws often require lights, brakes, and proper hitch safety chains. Even on private property, consider brake-equipped trailers for heavier loads.

Typical applications & use cases

- Landscape businesses: Quickly tow landscape trailers, move equipment, and swap implements (e.g., aerator to box blade) using a 3-pt quick hitch with a 2” receiver adapter.

- Hobby farms: Pull small livestock trailers, feed wagons, or utility trailers behind a subcompact tractor safely.

- Golf course or groundskeeping: Attach small material carts, utility trailers and tow mowers/tools.

- Construction site: Move materials in a small trailer, use drawbar for compact trailer maneuvering.

- Homeowner tasks: Hauling firewood or debris, snow removal attachments combined with a receiver for towing small wheelbarrow-style trailers.

Safety tips (non-negotiable)

- Never exceed rated capacity: Ignoring GTW and tongue weight ratings risks structural failure and loss of control.

- Use rated pins/locknuts: Cheap or wrong-size pins can shear under load.

- Distribute load correctly: Aim for 10–15% tongue weight on trailers to maintain stability.

- Check clearances: Ensure the hitch doesn’t reduce ground clearance or interfere with steering and PTO if used simultaneously.

- Use safety chains: Always cross chains under the coupler to catch the tongue if it detaches.

- Regular inspections: Check welds, fasteners, and pins frequently — especially after heavy use.

- Brake control: For heavier trailers, trailer brakes and a control system are strongly recommended.

- Park & unhook safely: Lower the 3-point to the ground or use stands when uncoupling to prevent accidental descent.

Maintenance & care

- Lubrication: Grease pivot points and bushings periodically to prevent wear and corrosion.

- Rust prevention: Keep hitches painted or coated; touch up scratches to avoid deterioration.

- Torque & hardware checks: Re-torque mounting bolts after the first few hours of use and check pins/retaining clips often.

- Storage: When not in use, store adapters and removable components in a dry place to extend life.

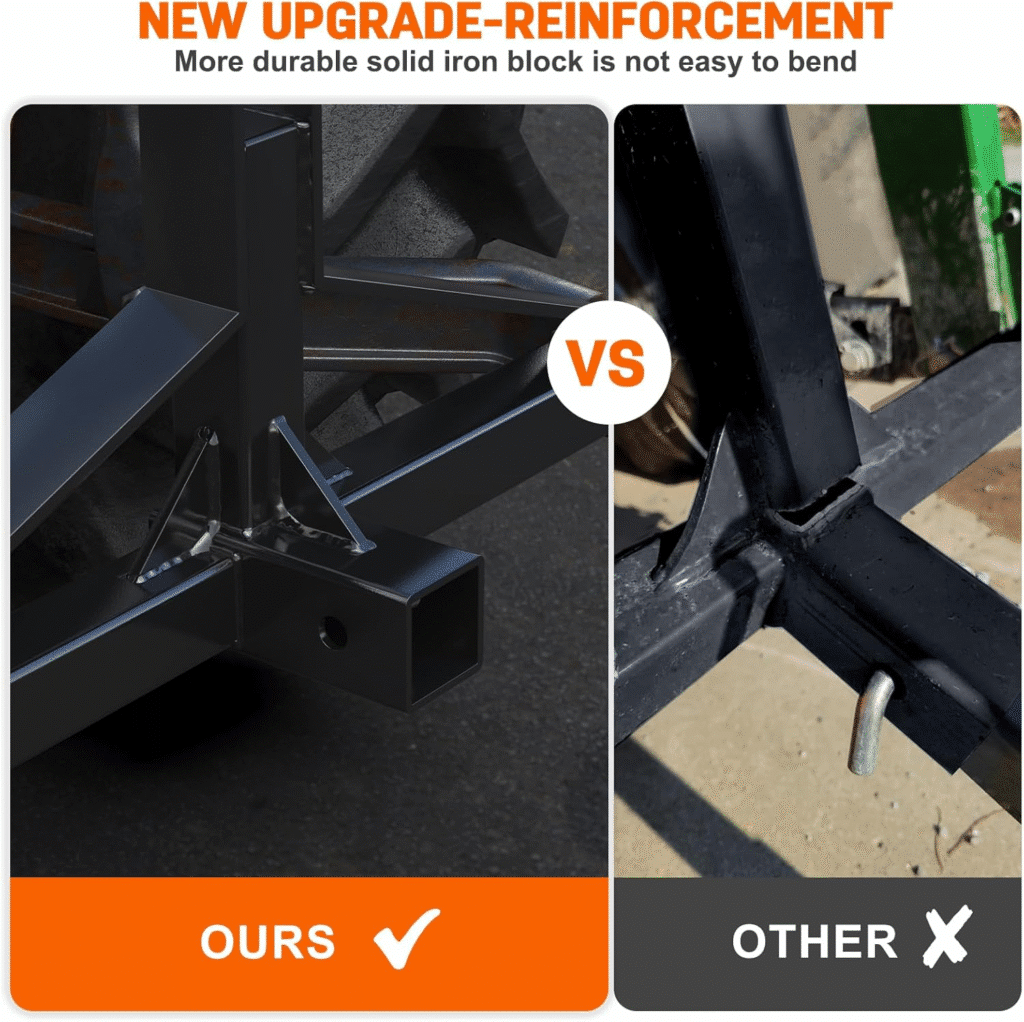

- Weld inspection: Look for hairline cracks at welds; replace if any structural compromises are found.

- Replace worn parts: Bushings, pins, and hitch balls wear over time—replace before failure.

Frequently Asked Questions (short answers)

Q: Can I tow a trailer on roads with a subcompact tractor?

A: Local regulations vary. Many jurisdictions limit road speeds and require trailer lighting and brakes. Always check local laws and never exceed the tractor’s towing ratings.

Q: Is a 2” receiver safe on a 3-point hitch?

A: Yes—if using a receiver adapter designed for 3-point use, rated for Category 1, and installed per instructions. The adapter must preserve correct load geometry and ratings.

Q: What’s the difference between a quick hitch and a drawbar?

A: A quick hitch attaches implements to the 3-point quickly for implements like mowers, while a drawbar is a simpler towing bar that links directly to a trailer or coupler. Many users have both: quick hitch for implements, drawbar for trailers.

Q: Can I convert a Category 2 hitch to Category 1?

A: Adapters exist, but they must be used carefully. It’s safer to use equipment that matches the tractor’s hitch category.

Troubleshooting common problems

- Trailer swaying or fishtailing: Check tongue weight (likely too light), trailer loading, tire pressures, or hitch tightness.

- Difficulty attaching or detaching: Inspect for bent pins, corroded bushings, or misaligned lift arms; adjust top link length and alignment.

- Excessive play in hitch: Worn bushings or oversized pins are typical causes; replace worn parts.

- Noise or grinding when towing: Check for missing lubrication or misaligned coupler/ball; tighten and grease components.

Final recommendations

If you own a subcompact or small compact tractor and frequently switch between towing tasks and mounted implements, investing in a good-quality 3-point quick hitch with a 2” receiver adapter plus a properly rated drawbar hitch is one of the best upgrades you can make. They multiply your tractor’s utility, save time, and — when selected and used properly — keep you safer on the job. Always match components to your tractor’s Category 1 specifications, honour rated capacities, and follow the manufacturer’s installation instructions.

Want a quick checklist to bring to the store or dealer? Here it is:

- Confirm tractor Category (likely Category 1 for subcompact).

- Note lift-arm pin diameter and top-link pin size.

- Confirm rated GTW and tongue weight of any hitch/adapter.

- Ensure receiver size = 2” if you want broad accessory compatibility.

- Check for corrosion-resistant finish and solid welds.

- Ask about warranty and spare parts.

- If towing on roads, ask about required lighting/brakes and local regs.

A well-chosen hitch system turns a small tractor into a flexible, safe, and time-saving tool. If you’d like, I can help draft a short shopping list of highly-rated models for Category 1 tractors, or a step-by-step installation checklist tailored to your tractor’s make/model — tell me your tractor model and whether you prefer a universal quick hitch or a brand-specific solution, and I’ll build that for you.